Heidi Schwegler is a self-described city person with an aversion to nature. Despite this, she can regularly be found working in far-flung, remote studios embedded in natural settings. In recent years, she has been a symposium participant at North Lands Creative Glass in the northernmost county of Scotland, was a resident at Yaddo in upstate New York, and was a fellow at the prestigious MacDowell Colony. It is not surprising then, that she recently found herself amongst the Douglas Fir trees at Pilchuck Glass School in Stanwood, Washington.

Heidi is the first recipient of the Klaus Moje Award, a scholarship to Pilchuck Glass School established by Bullseye Glass Company to honor Klaus Moje. It was at Pilchuck in 1979 that Bullseye’s founders first encountered Klaus. His ensuing visit to Portland became a pivotal point in the development of compatible glass and kilnforming as a method. Throughout Klaus’ life, he dedicated himself to his art and to education. This award, allowing an artist to learn and spend time at the school where this important connection was made, is a way of keeping Klaus’ memory alive.

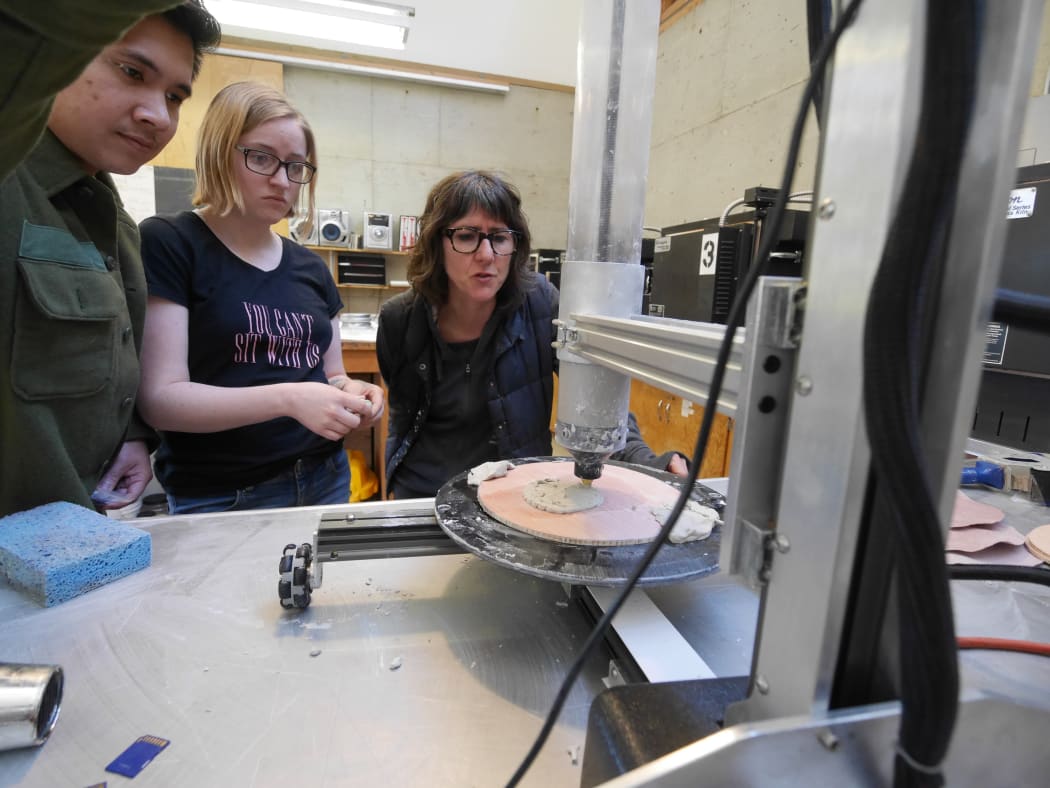

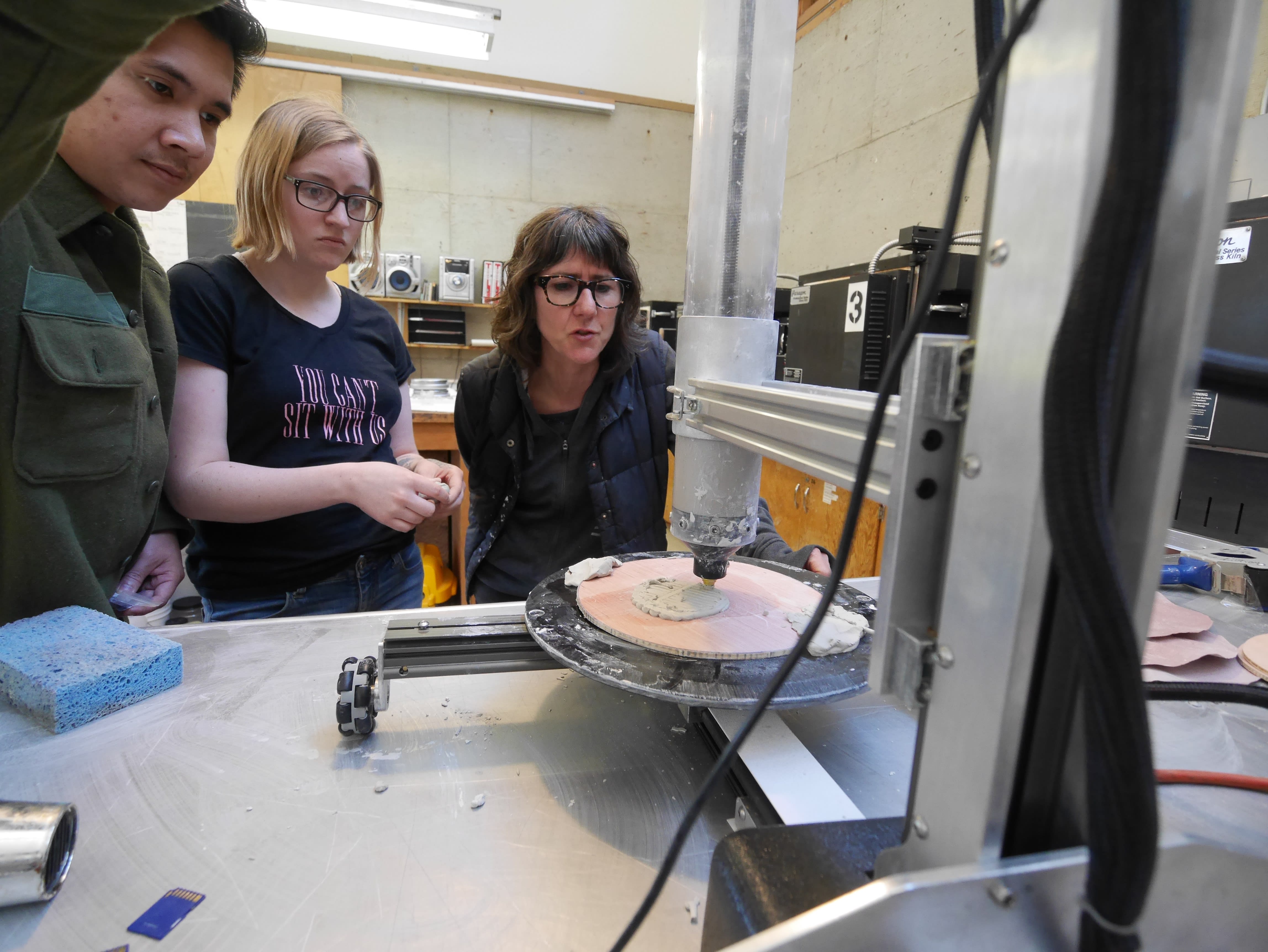

I am incredibly grateful for and honored to have received the Klaus Moje Award for the Digital Clayground workshop at Pilchuck this summer. Becca Arday, Phirak Suon and Barrak Darweesh were a brilliant team in that they were able to instruct us on topics as diverse as mold making, glass casting, pate de verre, Claybot and PLA 3D printing and Rhino and Meshmixer 3D rendering programs. They made it seem easy and introduced every stage in such a way that what could have been seen as opposing (craft tradition and digital technology), in the end made complete methodical sense. I never could have imagined that I'd be able to walk away after just over a week and manage these techniques and processes on my own, but this is definitely the case. I'm now ready to dive in and make it my own. Thank you to the Digital Clayground Team, Bullseye and especially Klaus Moje! - Heidi Schwegler

The Claybot was used to print models that would later be cast in glass.

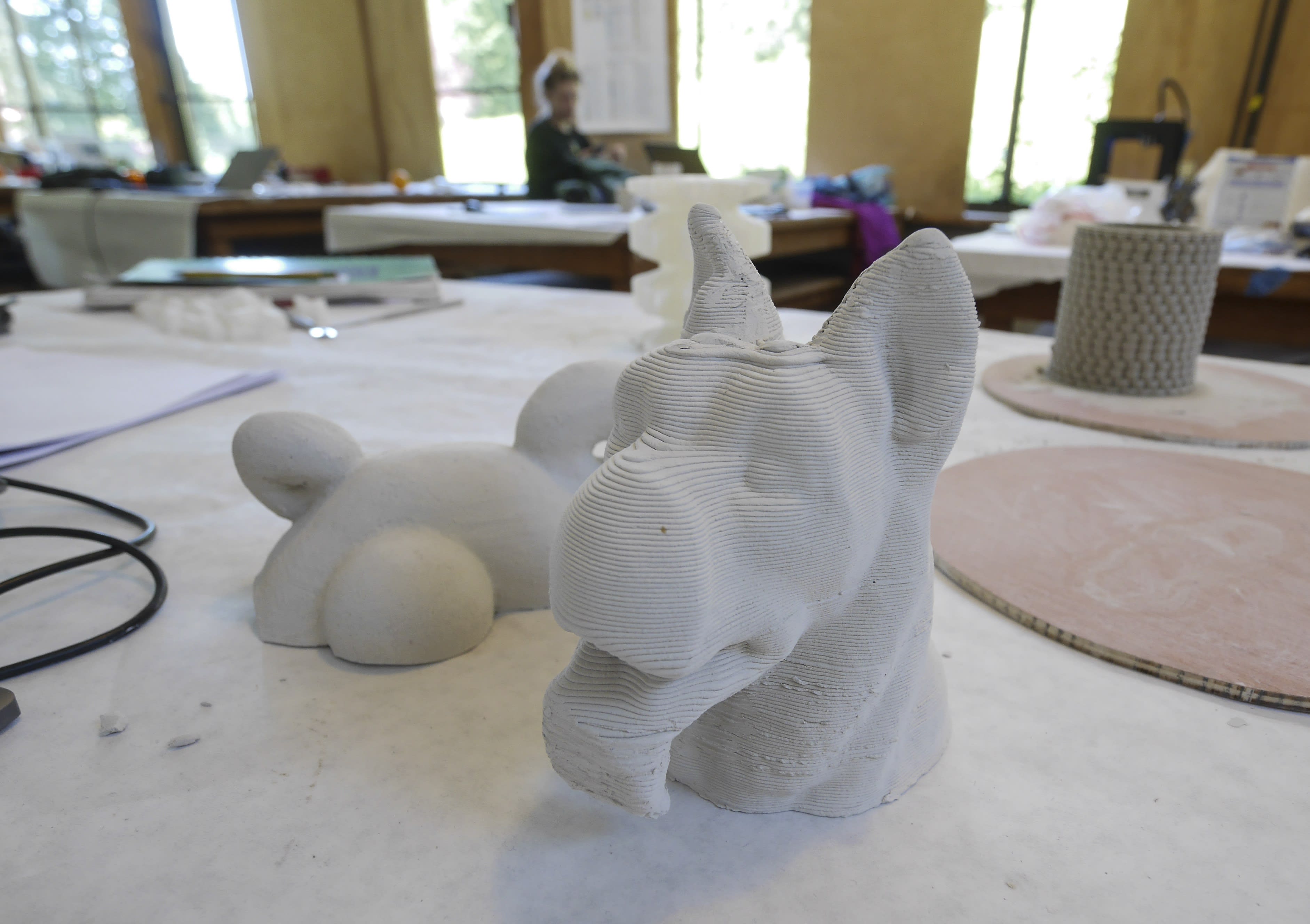

Claybot printed model.

Claybot printed model.

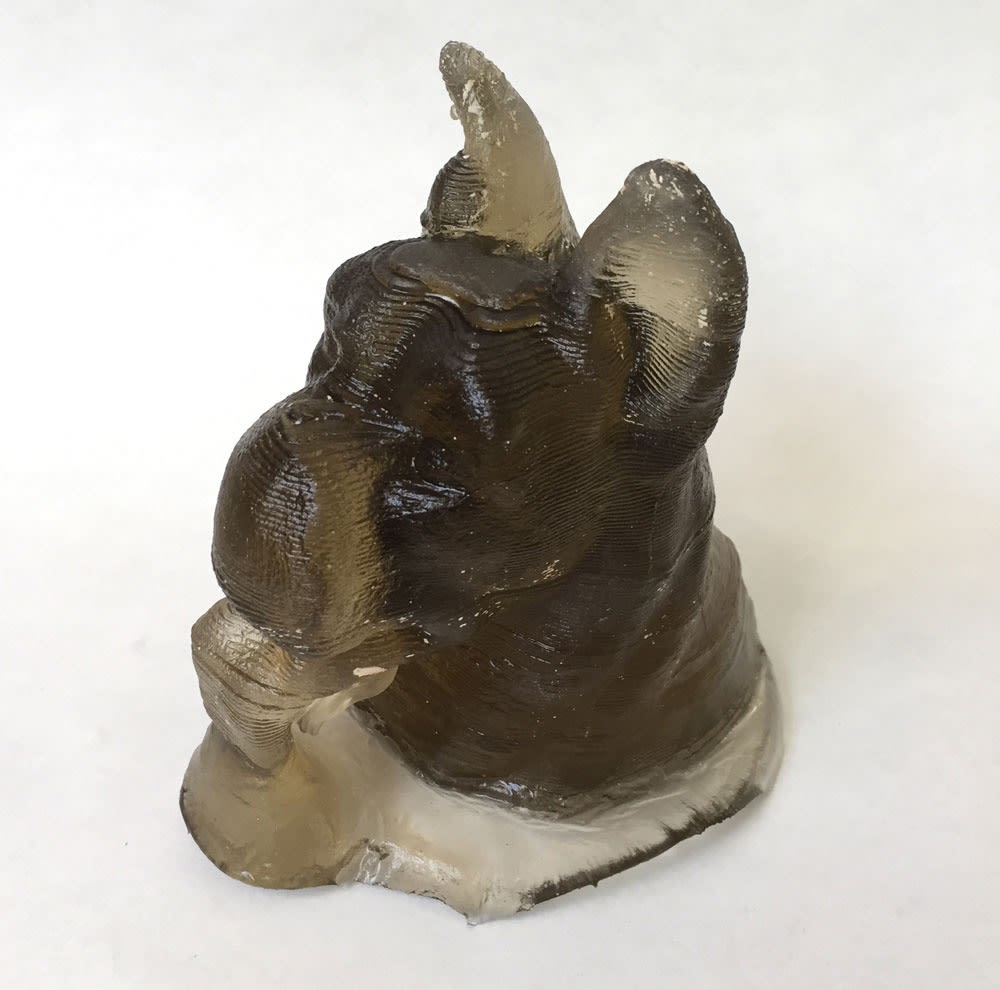

The model cast in glass.